1973 Sunoco-DX Mclaren AMT POS kit

Jul 18, 2019 11:49:12 GMT -5

indy, racerbrown, and 2 more like this

Post by starfighterace on Jul 18, 2019 11:49:12 GMT -5

After many starts and stops, this 1/25 AMT Sunoco McLaren POS was, by far, the worst model kit I ever tackled.

This is the 1973 Gary Bettenhausen Indy ride. I set out to detail it to the max. I always liked the Sunoco sponsored cars. I hadn't built this Indy Car kit before. I had built the Johnny Rutherford car as a kid. But this was the first issue of the kit and I liked the markings so much better than any of the Indy winning cars.

I did my homework. Read articles saying just how difficult this kit was. How is had so many issues with shape of the body, fit problems, bad tires, overly thick parts, and how it was best left alone. I took that as a challenge. I had tackled difficult Indy kits before: AMT '63 Lotus kit; MPC '68 Gurney Eagle, MPC Lotus 56 Turbine; and the AMT '74 STP Eagle. How could this be any worse? Oh my, yest it can.....

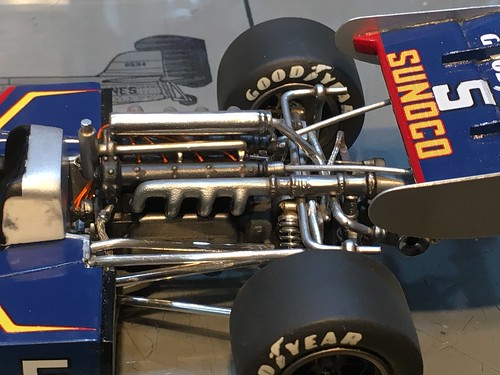

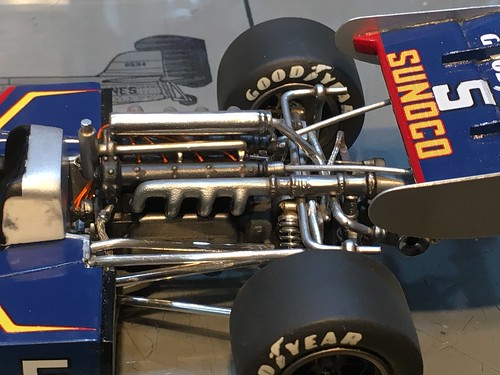

Body work was easy enough. Sand, fill, repeat. Built up the engine, wired it. Scratch built many of the radiators and coolers the kit was lacking. Made copious notes on the instructions as I reversed engineered the kit to make the assembly easier and more logical. Breaking down many of the steps into better sub-assemblies to avoid many of the fit problems. I replaced all of the kit suspension rods with Aluminum rods. The kit shocks were replaced with R&D Unique coil-overs. Tires were resin replacements from Lance Sellers. Decals were a combo of the (rather poor) Indycals, Fred Cady, and my home made replacements. I used MCW Sunoco Blue for the chassis and lots of different metallic paints for the engine. Wheels were Magnesium, not chrome, so I used Metalizer sealed with Semigloss Dullcote. In fact I stripped all of the chrome parts (Purple Power!) and re-chromed the actual parts that were chrome with Alcald or Bare Metal Foil.

Finally, I had the engine/rear suspension assembly ready to mate to the chassis/tub. Lined up the mounting points and..... wowza. It was skewed about 20 degrees off. Well, pooh. So I twisted the aluminum rods a bit, messed with the suspension and mounting points on the tub and got 'er level. Whew, glad I didn't use the plastic rods. Next up was the complex Turbo/exhaust. It didn't fit. Not even close.

Ended up taking more aluminum rod and solder, bending it, shaping it to replace the kit parts and match the pictures and diagrams I had for the Drake Offy. Took a few nights of test fitting, lots of ruined aluminum rod, and many new combinations of curse words before I was happy.

It had been 8 months of on and off working on this kit. I was about finished and it was looking good. This was 2013 ( I Think) and hoping to have it ready for the IPMS/USA Nationals...

Time to put the rear wing on. Another one of those separate sub-assemblies that was ready to go. Go to attach the wing and , what? The supports and the exhaust were suppose to occupy the same space? What idiot designed the kit to do that? The upper wing supports attached the the top of the Engine covers. The main exhaust went directly aft. Unless the rear wing was to angle upwards, it wasn't going to fit. If you did, the bottom wing attachment would not fit to the gearbox. In the US Military, there is a saying for something like this situation: "Charlie Foxtrot" As you see in the photos, this required a major re-work of both the rear wing supports and exhaust. So I shelved it. I had enough.

Two years later after working on some build-ups for a Resin car company I discovered a way to fix that problem. It worked. Involved a jig, careful cutting of the wing supports, cannibalizing a third AMT McLaren kit, and more patients. Home free I thought. I go to put the tires on and the left rear was about 5 degrees up in the air. The way AMT molded the rear suspension, the fix I made to get the engine/suspension/tub to sit level and true messed this up. I had the hammer in hand to bust it up. Salvage all of the parts I used: the Detail Master Disc Brake rotors, RM&Co resin brake calipers, R&D Unique coil overs; rebuilt dash with new steering rack; and so on. Back in the box it goes. Gave up on car models. I was defeated.

About 2 months ago while working on another car project after regaining my "car modeling mojo" with 1/43 and some OOB projects, I ran into a problem with another old kit and fit/alignment problem. This time the fix was logical, easy, and risky.

I am a member if a Internet modeling club. These guys build amazing aircraft modelers. Many are IPMS/USA award winners many times over and judges. One member ran into an alignment problem with is aircraft model. The literately cut off the wing

and reattached it to the correct the flaw. Another fixed a problem with his canopy (clear plastic, not the frame) the same way. Saw it off with a microsaw and reattach. That's what I did with the engine wouldn't fit thru this suspension part (This case it was an instructions flaw that was corrected in later re-issues of the kit). Voila', I now had a fix to the Sunoco McLaren suspension problem.

It was tricky, very risky, and messed up a bit. However, the car now sits on all 4 wheels, is aligned and (mostly) square. I had to use 5min epoxy to re-attached the spindle and lost some of the details. But I have prevailed over this kit.

In the intervening years, Indycals made a 3D Printed engine/suspension fix for this kit and another company has released a full resin kit of this exact car. Mine has neither. It is the AMT kit with only Lance Sellers Resin wheels and tons of aftermarket photoetch and scratch built parts.

I can say, I won't be building another one of these AMT McLaren kits ever again!

This is the 1973 Gary Bettenhausen Indy ride. I set out to detail it to the max. I always liked the Sunoco sponsored cars. I hadn't built this Indy Car kit before. I had built the Johnny Rutherford car as a kid. But this was the first issue of the kit and I liked the markings so much better than any of the Indy winning cars.

I did my homework. Read articles saying just how difficult this kit was. How is had so many issues with shape of the body, fit problems, bad tires, overly thick parts, and how it was best left alone. I took that as a challenge. I had tackled difficult Indy kits before: AMT '63 Lotus kit; MPC '68 Gurney Eagle, MPC Lotus 56 Turbine; and the AMT '74 STP Eagle. How could this be any worse? Oh my, yest it can.....

Body work was easy enough. Sand, fill, repeat. Built up the engine, wired it. Scratch built many of the radiators and coolers the kit was lacking. Made copious notes on the instructions as I reversed engineered the kit to make the assembly easier and more logical. Breaking down many of the steps into better sub-assemblies to avoid many of the fit problems. I replaced all of the kit suspension rods with Aluminum rods. The kit shocks were replaced with R&D Unique coil-overs. Tires were resin replacements from Lance Sellers. Decals were a combo of the (rather poor) Indycals, Fred Cady, and my home made replacements. I used MCW Sunoco Blue for the chassis and lots of different metallic paints for the engine. Wheels were Magnesium, not chrome, so I used Metalizer sealed with Semigloss Dullcote. In fact I stripped all of the chrome parts (Purple Power!) and re-chromed the actual parts that were chrome with Alcald or Bare Metal Foil.

Finally, I had the engine/rear suspension assembly ready to mate to the chassis/tub. Lined up the mounting points and..... wowza. It was skewed about 20 degrees off. Well, pooh. So I twisted the aluminum rods a bit, messed with the suspension and mounting points on the tub and got 'er level. Whew, glad I didn't use the plastic rods. Next up was the complex Turbo/exhaust. It didn't fit. Not even close.

Ended up taking more aluminum rod and solder, bending it, shaping it to replace the kit parts and match the pictures and diagrams I had for the Drake Offy. Took a few nights of test fitting, lots of ruined aluminum rod, and many new combinations of curse words before I was happy.

It had been 8 months of on and off working on this kit. I was about finished and it was looking good. This was 2013 ( I Think) and hoping to have it ready for the IPMS/USA Nationals...

Time to put the rear wing on. Another one of those separate sub-assemblies that was ready to go. Go to attach the wing and , what? The supports and the exhaust were suppose to occupy the same space? What idiot designed the kit to do that? The upper wing supports attached the the top of the Engine covers. The main exhaust went directly aft. Unless the rear wing was to angle upwards, it wasn't going to fit. If you did, the bottom wing attachment would not fit to the gearbox. In the US Military, there is a saying for something like this situation: "Charlie Foxtrot" As you see in the photos, this required a major re-work of both the rear wing supports and exhaust. So I shelved it. I had enough.

Two years later after working on some build-ups for a Resin car company I discovered a way to fix that problem. It worked. Involved a jig, careful cutting of the wing supports, cannibalizing a third AMT McLaren kit, and more patients. Home free I thought. I go to put the tires on and the left rear was about 5 degrees up in the air. The way AMT molded the rear suspension, the fix I made to get the engine/suspension/tub to sit level and true messed this up. I had the hammer in hand to bust it up. Salvage all of the parts I used: the Detail Master Disc Brake rotors, RM&Co resin brake calipers, R&D Unique coil overs; rebuilt dash with new steering rack; and so on. Back in the box it goes. Gave up on car models. I was defeated.

About 2 months ago while working on another car project after regaining my "car modeling mojo" with 1/43 and some OOB projects, I ran into a problem with another old kit and fit/alignment problem. This time the fix was logical, easy, and risky.

I am a member if a Internet modeling club. These guys build amazing aircraft modelers. Many are IPMS/USA award winners many times over and judges. One member ran into an alignment problem with is aircraft model. The literately cut off the wing

and reattached it to the correct the flaw. Another fixed a problem with his canopy (clear plastic, not the frame) the same way. Saw it off with a microsaw and reattach. That's what I did with the engine wouldn't fit thru this suspension part (This case it was an instructions flaw that was corrected in later re-issues of the kit). Voila', I now had a fix to the Sunoco McLaren suspension problem.

It was tricky, very risky, and messed up a bit. However, the car now sits on all 4 wheels, is aligned and (mostly) square. I had to use 5min epoxy to re-attached the spindle and lost some of the details. But I have prevailed over this kit.

In the intervening years, Indycals made a 3D Printed engine/suspension fix for this kit and another company has released a full resin kit of this exact car. Mine has neither. It is the AMT kit with only Lance Sellers Resin wheels and tons of aftermarket photoetch and scratch built parts.

I can say, I won't be building another one of these AMT McLaren kits ever again!