|

|

Post by lolagt00 on Feb 10, 2021 14:47:56 GMT -5

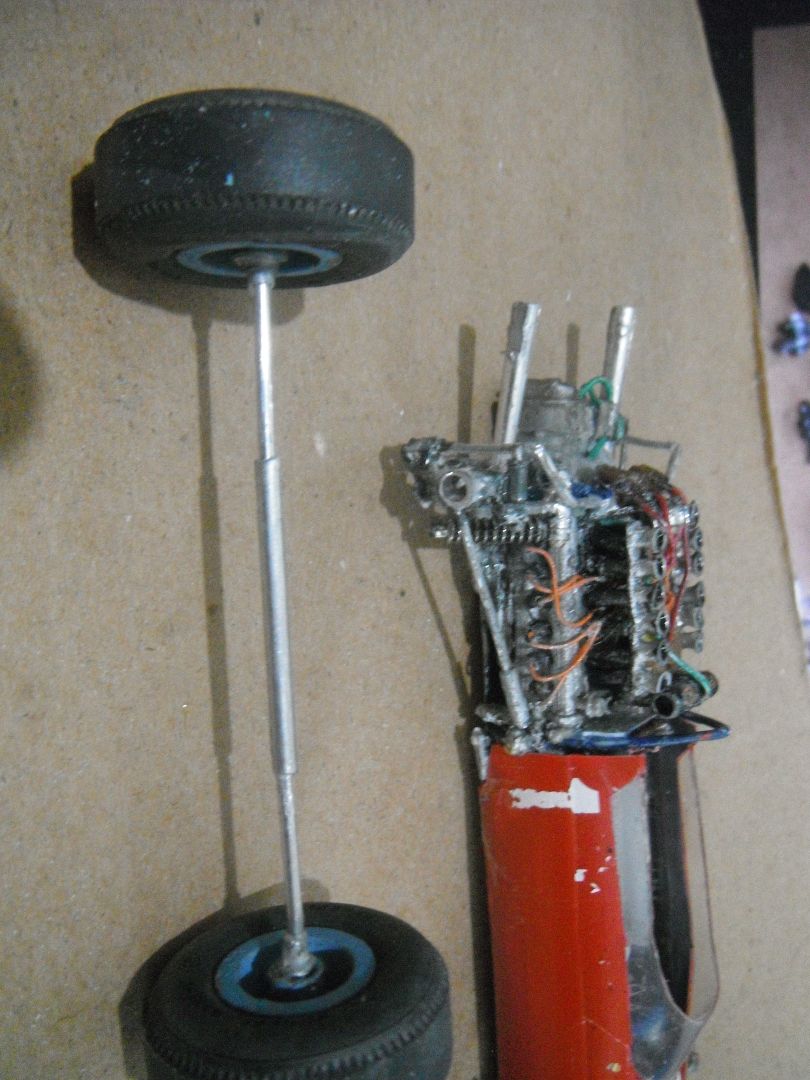

Morning Fellows, Doing my THIRD complete rebuild of my 64/65 Ferrari 1512 rear suspension. The AMT Lotus 29 parts are just too fragile. Major problem is Lotus Half Shafts are too big diameter vice Ferrari. I drilled out all A-arm and mounting points and used 090 brass screws and nuts. Trailing arms kept snapping so replaced with K & S #5497 steel rod with ends bent to insert in tub and rear bent to allow suspension upright lower to attach A-arm outer mounts. Drilled out half shaft holes in uprights to use aluminum #5103 sleeve 1/8 inch upright plastic will be thinner but stronger.

Just for the Hell of it, I used the Lexan transaxle from the repop 1512 slot body with an IMC Fords GT Colotti core. Ran a long about1/16 drill thru both uprights, thru the transaxle to align everything. I used the Cox wheels paint light blue with Cox slicks. I decided to drill out the wheels to fit #5102 tube, I made half shafts from #8100 1/16 tube. I made a about 3/4 tube of #5102 3/32 tube for the transaxle center. I cut about 1/16 sleeves which I put on the half shaft ends where the enter the wheel sleeves. Lot of work cutting, grinding flat but now I have a strong axle and suspension mounts and the wheels revolve. I will do this process on all my open wheel cars. Have yet to do the fronts. Tried drilling out stub axles and using #090 brass screws but even low speed drilling melted the plastic. Will go to the Industrial hardware store and see if I can get some flat headed pins. Have to finish attaching the left side and fabricating R & L trailing arms. Please excuse the battered appearance, new decals coming.Thanx for viewing, John

|

|

|

|

Post by lolagt00 on Feb 11, 2021 14:11:30 GMT -5

ARGH: I Was getting the Left rear suspension damaged and overglued parts ready to install, when my computer started to go Haywire and the keys are sticking (time for new computer) and holding the Ferrari in my hand, I managed to crush the right hand rear suspension! ARGH (again). So now I'm seeing what is salvageable. Glad I got my Micro Drill bits from Harbor Freight, if you can find them get 'em! Great for 090 screws. OK, Starting the FORTH rear suspension rebuild, wish me Luck.

|

|

|

|

Post by jimhamill on Feb 11, 2021 15:26:13 GMT -5

Murphy is alive & doing his mischief!

Can't remember ever doing that but have memories of accidentally wiping out hours of work

Only saving grace was I usually did a better job the 2nd time so ended up being satisfied

Hope your 3rd time on that suspension is the charm!

Jim

|

|

|

|

Post by lolagt00 on Feb 14, 2021 19:37:25 GMT -5

FINALLY!!! Rebuilt the entire rear suspension with new AMT radius rods, still still managed to break one so I sleeved it with aluminum tubing where it don't show.The problem with the Ferrari and Lotus is flat 12 and V8 differences in spacing the transaxle (TA) and half shafts causes stress in the radius rods Lotus are just a trifle short. The biggest problem was running a main center tube in the TA with a smaller longer center tube then run the smaller diameter half shafts. The uprights wanted to pull forward so I align drilled the half shaft holes with the uprights,inserted aluminum sleeves in the uprights that were thinned out. Waiting for epoxy inside transaxle to harden then run the rear wheels with half shafts inserted,then I'm done! The Front wheels were easier than I initially thought. Since the Ferrari doesn't have knockoffs and I wanted rotating Cox wheels, I drilled out the Lotus front axles. Easier said than done, the Harbor Freight mini drill though small runs at 16000 RPM! Which melts the micro bit holes shut and the drills only last a month then burn up the bearings. Bought a variable speed but too bulky. Found a variable speed CORDLESS at HF, works great! So used 090 brass screws with washer outside the hub. Fronts good to go. WHEW!!!!

|

|

|

|

Post by lolagt00 on Mar 18, 2021 14:04:12 GMT -5

|

|

|

|

Post by indy on Mar 18, 2021 15:31:12 GMT -5

John, sad to see you frustrated with this one. Glad you got it done and on the shelf. Looking forward to you building, it is always inspiring to come here and see a WIP, even when there are challenges.

Jordan

|

|